Jun. 12, 2025

Hydroxypropyl Methylcellulose (HPMC) plays a vital role in construction, especially as a thickening agent. However, viscosity changes in high temperature environments can lead to significant construction difficulties. These challenges arise due to reduced workability, inconsistent application, and prolonged setting times, causing issues for both HPMC manufacturers and end-users. Understanding these effects is critical to addressing the challenges.

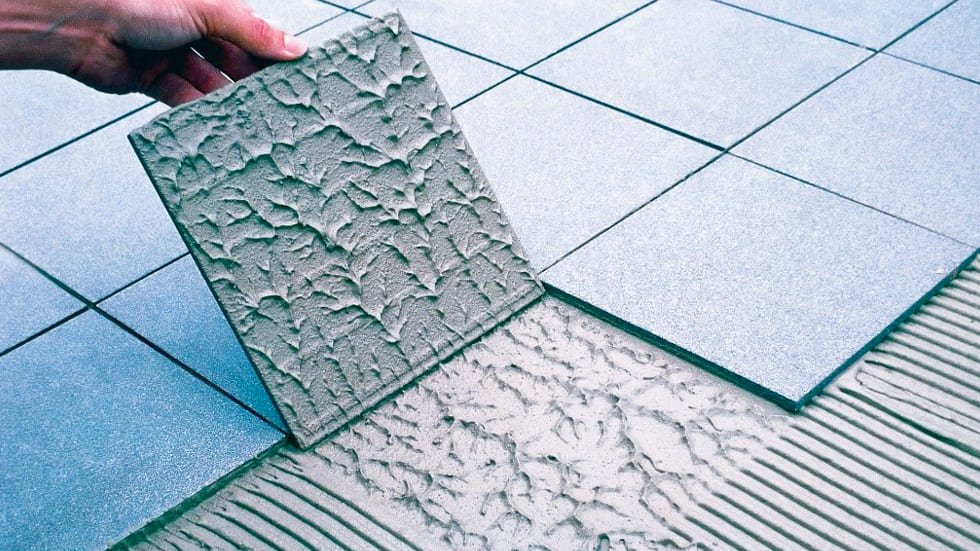

HPMC is a cellulose-derived polymer widely used in building materials, such as cement mortars and adhesives. Its viscosity is essential for maintaining product stability and performance. Key factors affecting HPMC viscosity include temperature, grade, and concentration.

HPMC viscosity can be classified based on solution concentration and temperature. At elevated temperatures, viscosity decreases, leading to various application challenges.

| Temperature (°C) | Viscosity (cP) |

| 20 | 2000 |

| 40 | 1500 |

| 60 | 1000 |

| 80 | 500 |

High temperatures can drastically alter HPMC viscosity, resulting in several detrimental effects during construction. These factors include:

Reduced Workability: HPMC solutions become less viscous, making them harder to manipulate.

Inconsistent Application: Variability in viscosity leads to uneven mixing and application.

Prolonged Setting Times: Lower viscosity can prolong drying and setting time, delaying construction schedules.

In an extreme application, a construction site under high temperatures experienced setting issues, causing a delay in project timelines. Viscometric tests showed a 40% reduction in HPMC viscosity compared to standard conditions.

When HPMC viscosity changes, practical difficulties arise:

Increased Labor Costs: Workers require additional time and effort to apply lower-viscosity solutions.

Material Waste: Uneven application can lead to increased waste due to improper adhesion.

Quality Control Issues: Variations in product quality become evident, leading to potential reworks.

To combat the difficulties posed by viscosity changes in high temperatures, consider the following solutions:

Product Selection: Choose HPMC grades specifically formulated for higher thermal stability.

Temperature Management: Implementing temperature control measures on site can help stabilize viscosity.

Application Techniques: Adjusting mixing and application techniques may enhance workability.

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Chemical Industrial Park, Xinji City, Hebei Province, China Post Code: 052360

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. All Rights Reserved