HPMC is white or light yellow powder. When mixed with water, it can form a colorless and transparent gel. HPMC powder is flammable and non-explosive. It is a little smelly when burning. After burning, the black-gray residue will be left.

HPMC has water-retention ability. Hydroxypropyl molecular groups and methoxy molecular groups can effectively lock moisture and delay its evaporation.

HPMC has a thickening ability and can thicken water solution into a gel. The gel has a certain adhesive force, but it is very small and can only bond paper.

●By Applications

constructional grade; daily-care grade, pharmaceutical grade

●By Production methods: vertical reactor and horizontal reactor

HPMC’s production machines include vertical reactors and horizontal reactors. What are the differences between them?

The reactors for chemical production are generally closed containers. They can bear high temperatures and high pressure and perform chemical reactions.

The vertical reactor, as the name suggests, is vertical. It uses the solvent method, whose finished products have low viscosity, good transparency, and high degree of substitution.

Horizontal reactors are placed horizontally just as their name, which uses the gas phase method. And the HPMC produced here is of high viscosity, relatively low transparency and slightly low degree of substitution.

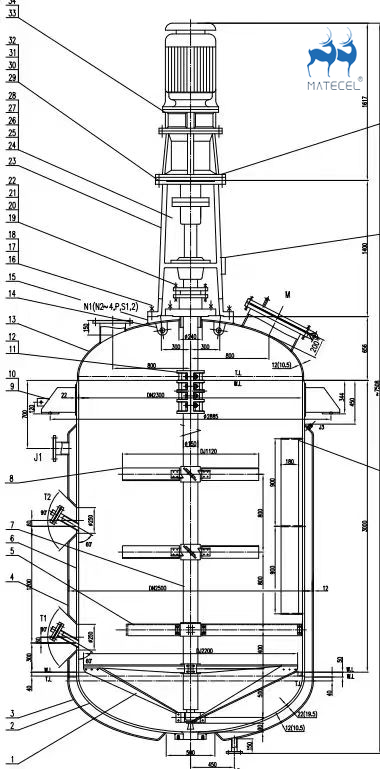

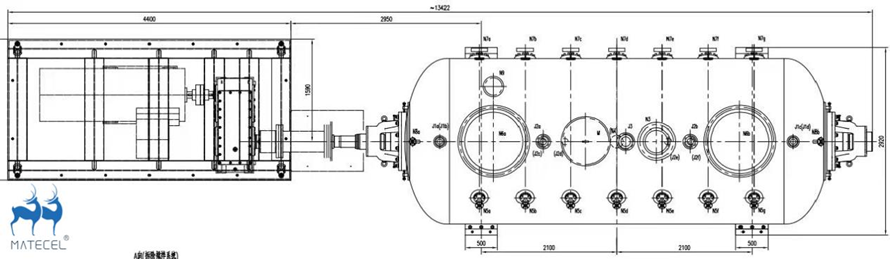

To help you understand better, the structural drawings and actual photos of the two reactors are shown below:

Vertical Reactor’s Structure Drawing

Vertical Reactors’ Actual Photo

Horizontal Reactor’s Structure Drawing

Horizontal Reactors’ Actual Photo

●By Surface-treated or not

Common HPMC, the grades without S, hasn’t been surface-treated. They are usually used in tile adhesive, mortar, or other dry-mix materials.

Instant dissolving HPMC, the grades with S, is surface-treated by the dispersant. It can be dispersed by cold water and is applied in daily care products and other water-based materials.

Five important indicators of HPMC: methoxyl content, hydroxypropyl content, ash content, moisture, gel temperature, PH value

The following are the methods and processes for testing the five major indicators of HPMC.

1.Make an internal standard solution

Accurately weigh 2.5 grams of toluene (accurate to 0.0001g), add it to a 100ML volumetric flask, dilute it to the mark with o-xylene, and then invert it up and down several times to mix evenly.

2.Use headspace bottle A to prepare the standard solution

1) Add 0.06g-0.07g of adipic acid to a 10ML 10-headspace bottle, and then accurately drip in 2.0ML internal standard solution and 2.0ML hydriodic acid with a pipette. Weigh or tare with a balance

2) Use a micro syringe to inject 45 microml of methyl iodide into the headspace bottle 2.1), and accurately weigh methyl iodide.

3) Use a micro syringe to continue injecting 15 micromol of Isopropane iodide into the headspace bottle 2.2), and accurately weigh Isopropane iodide.

4) Cap the headspace bottle A, shake evenly, and place it in a dark place for more than 30 minutes before usage.

3. Use headspace bottle B to prepare a sample solution

1) Weigh 0.065g of sample HPMC that has been dried at 105°C in headspace bottle B, and then add 0.06g-0.07g adipic acid

2) Use a pipette to absorb 2.0 ML of internal standard solution and 2.0 ML of hydriodic acid into headspace bottle B. Cap it tightly and weigh it accurately.

3) Shake the headspace bottle B for 30 seconds, then place the headspace bottle B in a drying oven whose temperature has been adjusted to 150°C for 20 minutes. Take out the headspace bottle B and shake it for 30 seconds, then place it in the drying oven to continue the reaction for 40 minutes. Take out the headspace bottle B, cool it to room temperature, and weigh it (requirements are the same as step 3.2, and the weight loss is not more than 0.01 grams, otherwise the sample solution needs to be prepared again)for later use.

4. Start measuring the standard solution in step 2 with a chromatograph for 3-5 times.

Standard deviation/average value = relative standard deviation (less than 0.5 proves that the standard solution is qualified)

5. Use a chromatograph to start measuring the sample solution in step 3, and obtain the average value of the peak area 3-5 times.

Methoxy group content W1, the value is expressed in %, calculated according to the following formula

W1=31/142×Q1/A1×A2×M1/M2×100%

Note:

Q1--The weight ratio of methyl iodide to toluene in the standard solution (Q1=0.1003×99%÷0.05)

A1--The ratio of the peak areas of methyl iodide and toluene in the standard solution

A2--The ratio of the peak areas of methyl iodide and toluene in the sample solution

M1--The weight of toluene in the internal standard solution, in grams (0.05 grams)

M2--The weight of the sample in the sample solution, in grams (mass of the HPMC sample)

Hydroxypropyl content W2, the value is expressed in %, calculated according to the following formula

W2=75/170×Q2/A3×A4×M3/M4×100%

Note:

Q2--The weight ratio of isopropane iodide to toluene in the standard solution

A3--The ratio of the peak areas of isopropane iodide to toluene in the standard solution

A4--The ratio of the peak areas of isopropane iodide and toluene obtained in the sample solution

M3--The mass of toluene in the internal standard solution (0.05 g)

M4--The mass of the sample in sample solution, in grams (weight of HPMC sample)

※average using function AVERAGE

※Standard deviation using function STDEV

1. Use three 25ml crucibles.

2. Weigh the weight of the crucibles separately and record the resulting number as m1; also need to number those three crucibles.

3. Add an appropriate amount of sample to each crucible, weigh the crucibles that contain the sample, and record the weighing number as m2.

4. Place the samples-loaded crucible in the electric furnace and burn it for 1 hour.

5. Wait until the temperature of the crucible drops to room temperature, weigh it, and record the weighing number as m3

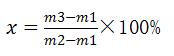

Ash content formula:

1. Test the moisture content detection bulton, make sure you zero the vessel's weight, add about 5 grams of HPNC to the weighing pan, and spread it evenly.

2. Click the automatic detection button, make sure you zero the vessel’s weight, add about 5 grams of HPMC to the weighing pan, and spread it evenly.

3. Click the Start Detection button

4. Wait unti the analzer automaticaly jumps to the completon page, and record the water loss rate, then you'l get the moisture content. %

1. Use an electronic scale to weigh 0.5g of cellulose and 50g of boiling water separately.

2. Pour the two materials above into a 300ml beaker, stir evenly with a glass rod, then add 200ml of tap water to the beaker and stir evenly until the temperature of the solution returns to room temperature.

3. Pour an appropriate amount of this solution into the test tube.

4. Place the test tube on the tube rack and place a direct-reading thermometer in the test tube, then suspend it in a beaker filled with tap water.

5. Use an electric stove to heat the beaker filled with tap water. When the solution in the test tube turns white very obviously, the temperature of the thermometer is the gel temperature.

1. Weigh 1 gram of HPMC, add it to 99 grams of hot water (water temperature above 80°C), and stir until it gains viscosity.

2. Cool the solution to about 10℃, and then heat it to 25℃

3. Place the pH meter into the HPMC solution at 25°C. After the data is stable, read the figure to find out the pH of HPMC.

Construction field:

●Tile adhesive

● Anti-crack mortar

●Self-leveling

●Putty powder

Daily chemicals:

●laundry detergent

●alcohol gel

Application of tile adhesive:

●Large addition of water amount. Currently, MATECEL products can add water up to 300 kilograms for tile adhesive per ton.

●Long opening time.

●Anti-slip.

●High pulling strength.

HPMC that meets the above four points is suitable and qualified for tile adhesive applications.

Laundry Detergent Application:

●General Recipe in China:

●General recipe for African markets:

HPMC for daily chemicals:

●The product looks good, white and fine, without small black spots.

●Delayed-solube HPMC, grade with S, have good dispersibility. When put into water, they will disperse quickly without clumping.

●Good transparency:the aqueous solution is clear and transparent.

●High viscosity: In the daily chemical system, it is important for the viscosity to be stable and does not degrade.

●Good stability: no delamination in the later stage.

Products that meet the above five points are good products for daily use.

The African market also has a unique formula. MATECEL has customized a daily chemical product specially for the African market. It has been proven by the market and is stable and reliable.

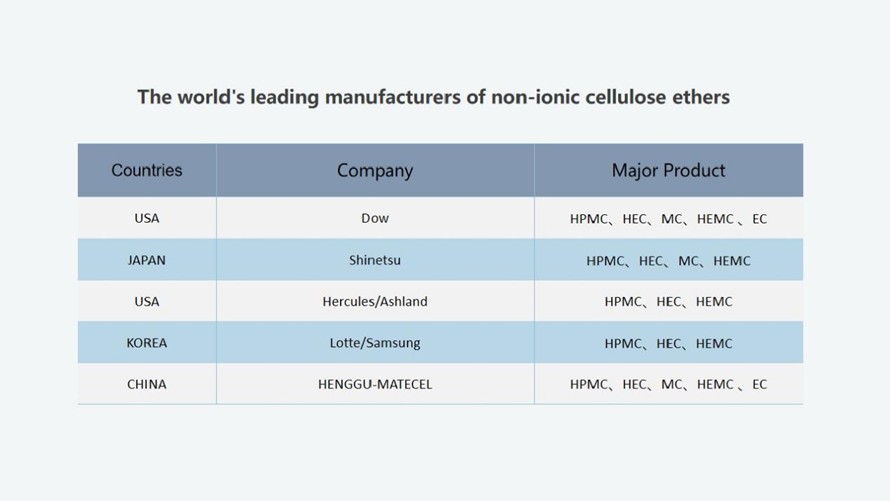

Main producing countries: United States, Germany, Japan, South Korea, China.

China has huge production capacity and is the only developing country among HPMC producing countries.

China's Henggu Jianxin Company is a professional and formal company, and its website is www.hpmc.com. Focusing on HPMC for many years, with reliable quality and R&D capabilities, we can provide corresponding product models according to customer needs.

MATECEL is its company brand—— MATE means friends and partners,CEL is the abbreviation of cellulose. Our company owns wide product range, strict testing procedures and a large-scale professional application laboratory and we ensure each batch of products is qualified before shipment. Our business philosophy: Let our partners (raw material suppliers, employees, customers) become better because of Matecel!

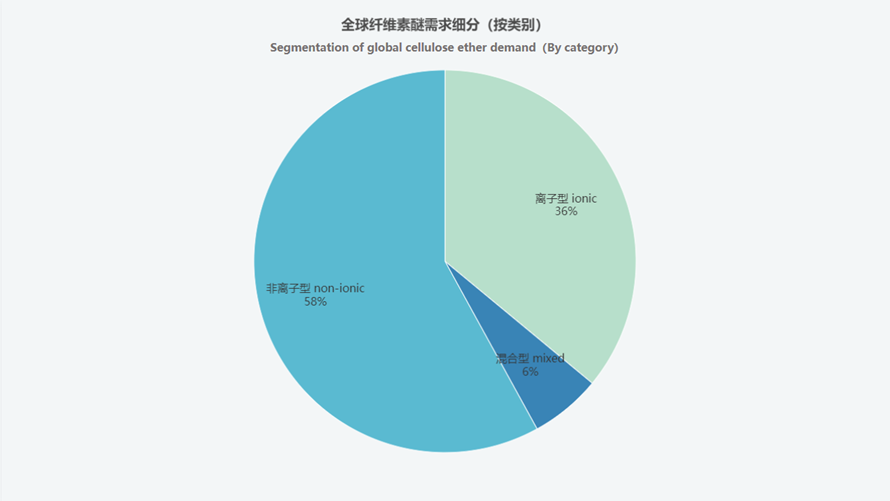

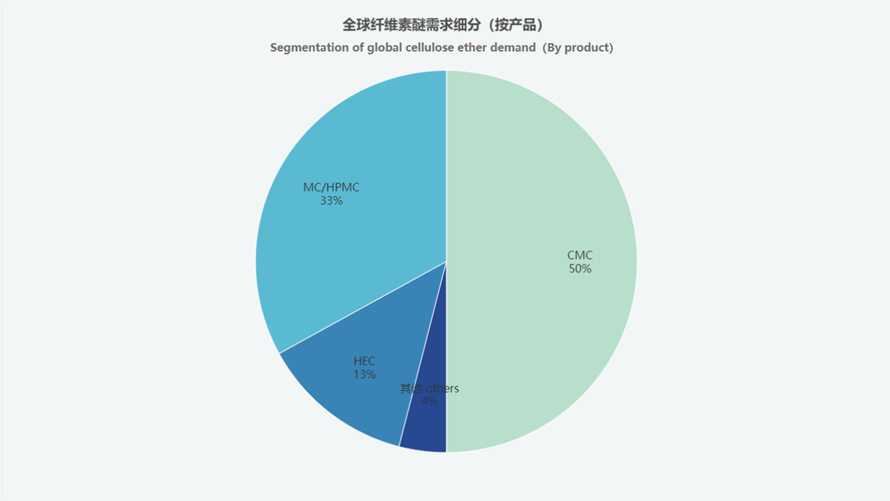

Globally, ionic cellulose ether account for the largest part of total production. In 2018, ionic cellulose ether accounted for 58% of total production, followed by non-ionic ones at 36%, and mixed ones at 6%. The mainstream cellulose ethers are CMC, HPMC, MC, HEC, etc. Among them, CMC has the largest output, accounting for about half of the global production, while HPMC and MC account for about 33% of the global demand, and HEC accounts for about 13% of the global market.

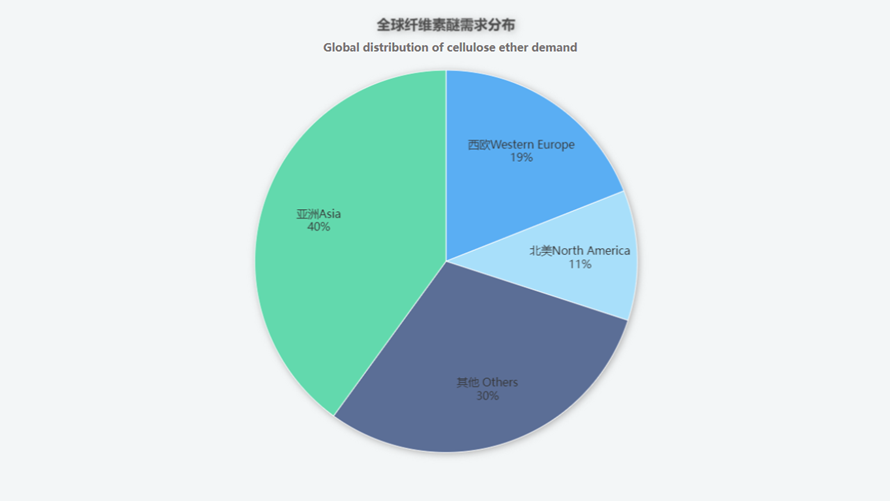

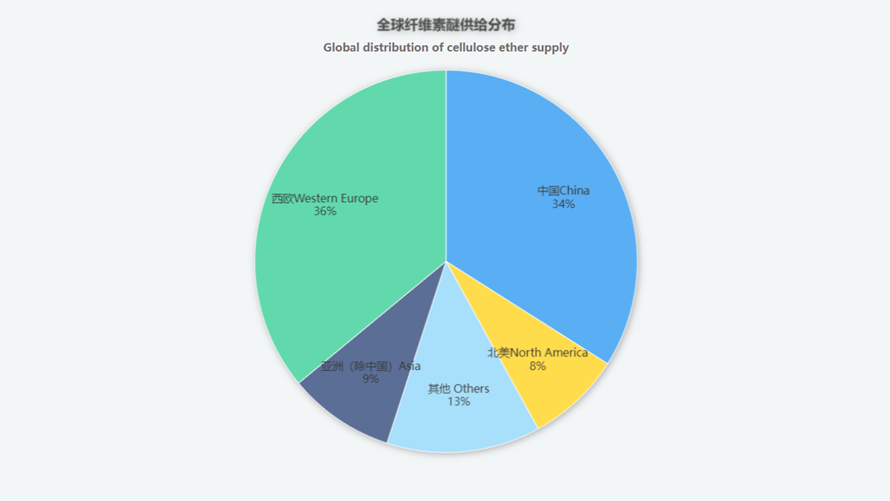

Geographically speaking, the Asia-Pacific region is the largest production and demand for cellulose ether. According to HS Markit, the global consumption of cellulose ether in 2018 was nearly 1.1 million tons. In 2018, 43% of the total global production of cellulose ether came from Asia (China accounted for 79% of Asian production), Western Europe accounted for 36%, and North America accounted for 8%. The largest region in the global consumption of cellulose ether in 2018 was Asia, accounting for 40% of the total consumption, with China being the most important driving force; Western Europe and North America account for 19% and 11% of global consumption respectively.

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Chemical Industrial Park, Xinji City, Hebei Province, China Post Code: 052360

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. All Rights Reserved