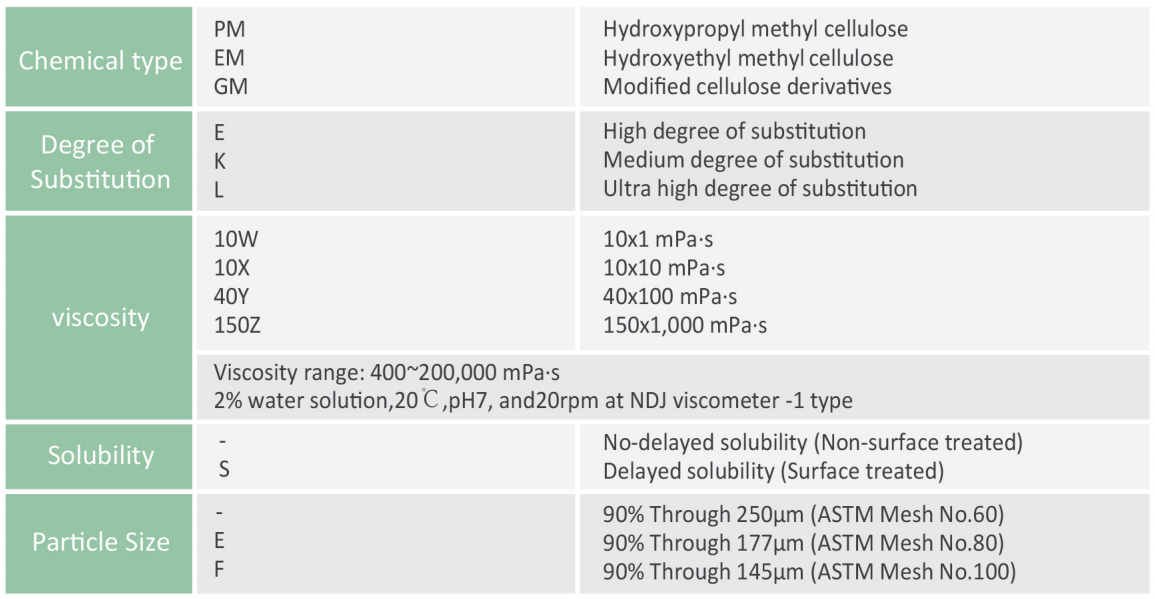

NOMENCLATURE & CLASSIFICATION

MATECEL® is classified into pure and modified grades. Pure grades are also divided into HPMC(Hydroxypropyl Methyl Cellulose) and HEMC(Hydroxyethyl Methyl Cellulose).

PMK-150ZS(HPMC, Degree of subsituion K, Viscosity 150000mPa·s, Delayed Solubility)

GMK Grade

GMK grades are finely modified to improve the rheological properties of cellulose ethers in accordance with various application requirements such as additional thickening, betier workability, less stickiness, longer open time, etc.

Modified grades are especially produced through chemical reactions, physical blending of organic or inorganic additives. The viscosity range varies from under 400mPa·s to over 200,000mPa·s.

Classification

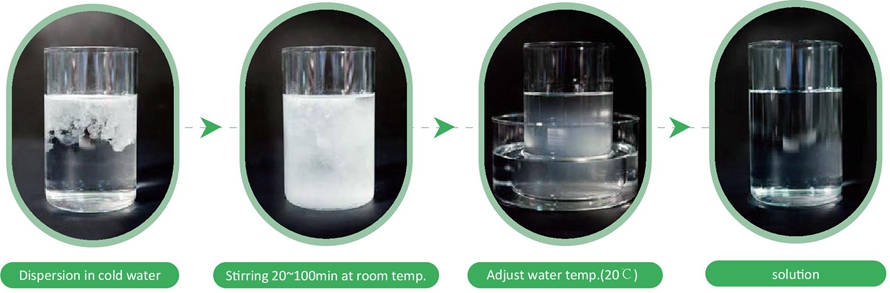

HOW TO PREPARE MATECEL® SOLUTIONS

Usually, non-surface treated MATECEL® can only be dispersed in hot water to prevent lumping, but surface treated MATECEL® can be dispersed in cold water.

In the meantime, have a look at the brief illustrations below to see the key differences.

Surface treated MATECEL®

Surface treated powder is specially developed to prevent lumping in wet blending applications such as paints and emulsion based applications. To

make the solution with surface treated powder, powder is directly placed into cold water. With time, a fully developed-solution with the appropriate

viscosity is prepared through continuous stirring of the solution.

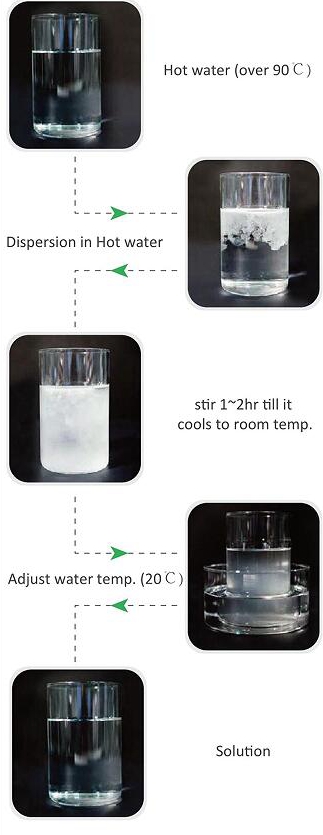

Non-surface treated MATECEL

If non-surface treated powder is put into cold water directly, it easily forms lumps due to its too quick solubility with cold water. To prevent lumping, put the powder into the hot water(over 90°C)first, then stir in order to disperse the powder, and then cool down the solution while stirring continuously.

When non-surface treated powder is used in a dry-mixing application, lumping is not a concern since each particle of MATECEL® is distributed throughout the final product evenly.

Adjustable Solubility Properties

Our HPMC products have adjustable solubility properties which vary from its degree of etherification.

SOLUBILITY

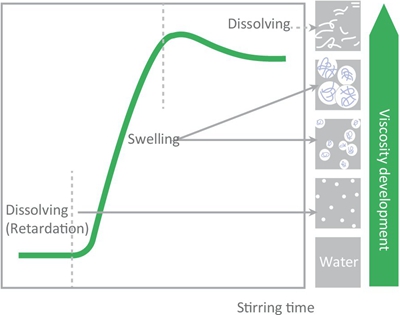

Dissolution of MATECEL®

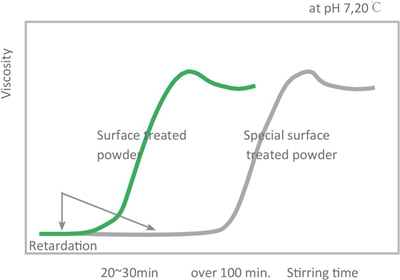

When it comes to water solubility levels and speed, the general dissolution mechanism of MATECEL® is shown in the graph below.

Non-surface treated MATECEL®

The viscosity measuring of non-surface treated MATECEL® is impossible in cold water due to lump formations. The retardation time of surface-treated MATECEL® Approximates to about 20 minutes at HP 7. However, the higher the PH of the solution is, the shorter the retardation time will be.

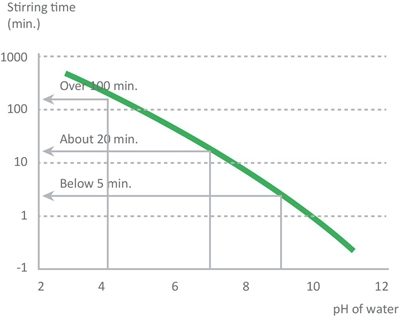

The effect of pH on MATECEL® dissolving times

The viscosity development time is dependent upon the pH of the solution fie surface- treated grades. The higher the pH of the solutions is, the shorter the retardation time will be. For paint applications, long-regarded grades are more suitable because of the high pH conditions (CaCO?,ammonia,etc.) of the applications.

VISCOSITY

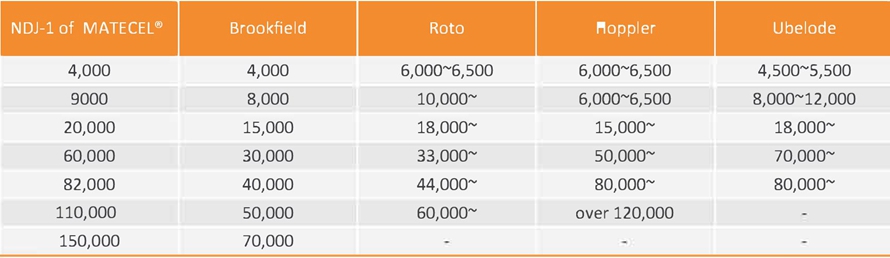

Viscosity comparison through various measurements

Viscosity is a resistance force (based on the flow rate, gravity force, rotation resistance of the product, etc.).

In general Hoppler (=Falling B) and Ubelode all types measure Newtonian solutions.

Note that measured values could vary with the types of NDJ viscometer

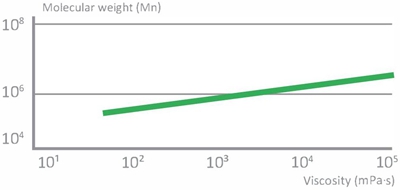

Relationship between viscosity and molecular weight

The viscosity of a solution is proportional to the weight or chain length of the MATECEL molecularAverage molecular weight of MATECEL varies from 400 to 200000.

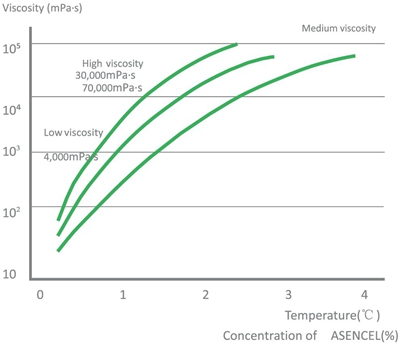

Relationship between viscosity and concentration

In general, viscosity is proportional to the concentration of the solution. Limited to about 2.5% for high viscosity grade.(over 50,000 mPas, 2% solution)

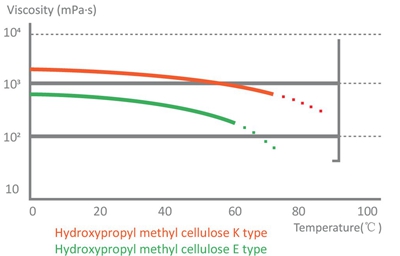

Relationship between viscosity and temperature

The viscosity of MATECEL solution depends on its temperature. As the temperature increases its viscosity gradually decreases when it reaches a certain temperature, the viscosity decreases sharply. The trend is shown in the dotted line. That certain temperature is called Gel-point.

MAIN BENEFITS

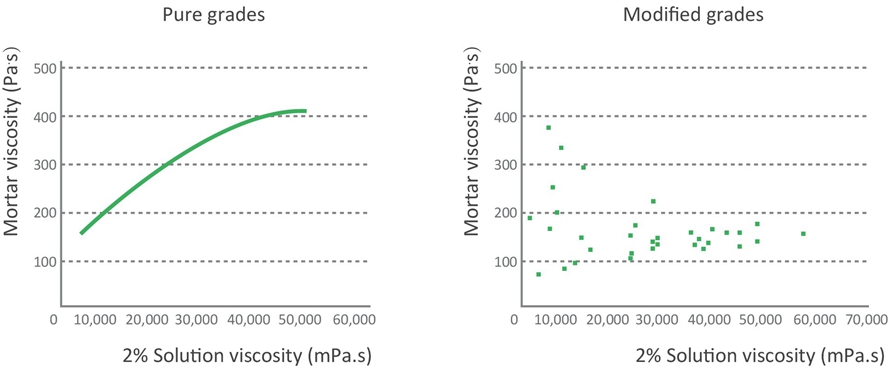

Thickening effect

MATECEL® is used very often as a thickener in building applications as it prevents segregation and improves the cohesion of the formulation components.

The viscosity of MATECEL® depends on the degree of polymerization, contraction, temperature, shear rate, concentration of dissolved salts, and modification.

In dry mixing production and mortar, the thickening power of pure grades is related to their solution viscosity. On the other hand, the mortar viscosity of modified grades is not necessarily proportional to the solution viscosity.

APPLICATION FIELDS

The adhesives

To provide excellent thickening efficiency, long open time and adhesion power.

Paints & Coatings

To be used as thickeners and pigment suspension aids. To improve the viscosity stability and dissolution of water based emulsion paints.

EIFS/ETICS

To provide excellent workability and long working time.

Personal care & Detergents

To be used as thickening, dispersing, and emulsifying agents for manufacturing lotions, shampoos, etc.

Plasters & Renders

To provide excellent workability and water retention.

Skim coat & Puty:

To provide high output in the application and long open time.

Ceramic & Cement extrusion

To provide water retention and lubricity during processing.

Self Leveling

To provide excellent liquidity and prevent water bleeding.

Tile Adhesives

MATECEL® promises the high performance and excellent working efficiencies for attachment of tiles to various substrates. Being slip resistance and having better open time is the key to better adhesive requirements.

These improvements can only be gained from MATECEL®.

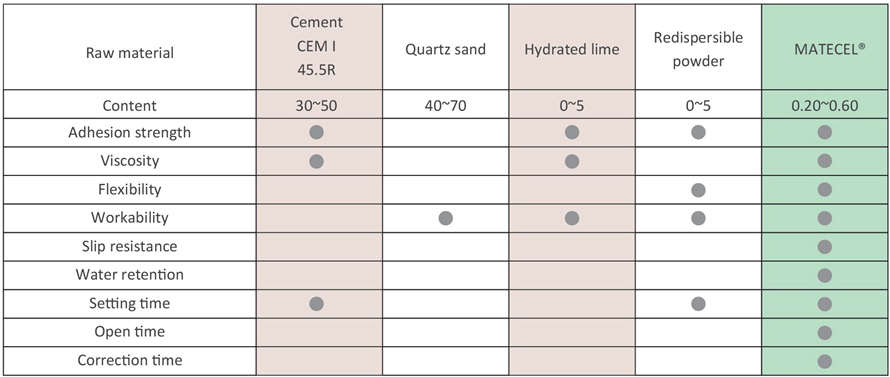

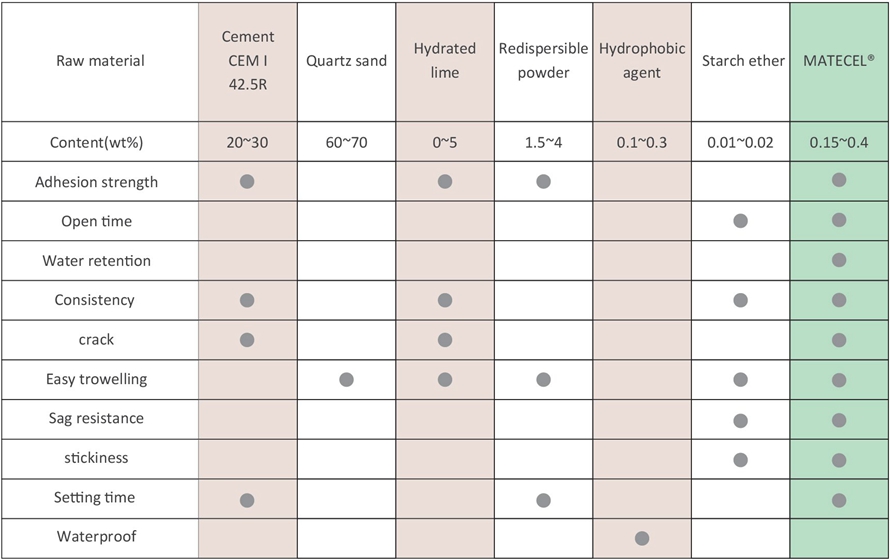

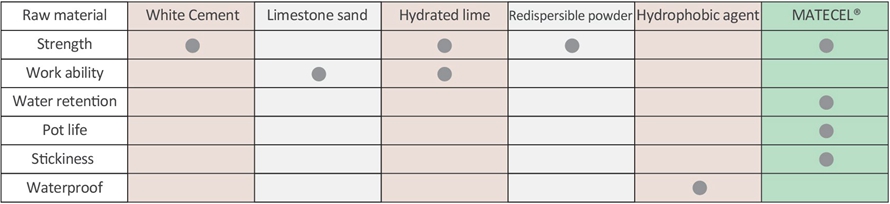

Effects of raw materials

Slip resistance

Slip resistance is crucial in order to improve working efficiency in applying tile cement mortars on walls. MATECEL® provides adhesives with better slip property so that tiles can be applied in a better way. With suitable MATECEL® grades and concentration levels, heavy tiles over 50 kg can be applied to walls without slipping.

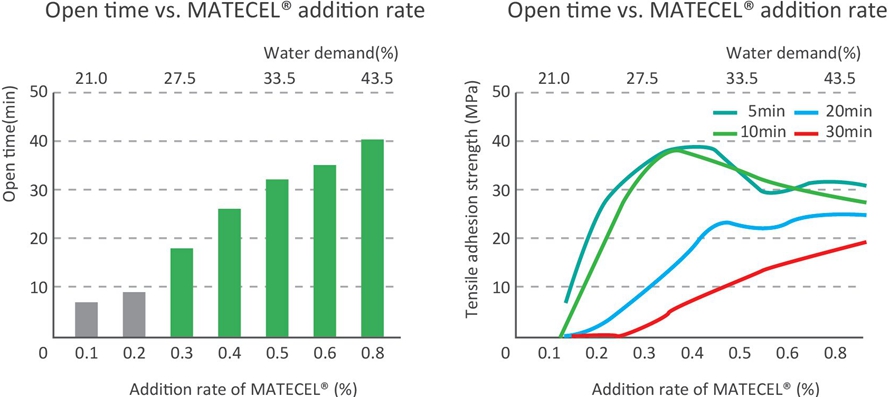

Open time & Tensile adhesion strength

MATECEL® cellulose prolongs the open time during construction,thus giving plenty of time for correction. Suitable addition rate of MATECEL® ensure longer open time, higher tensile adhesion strength and better workability.

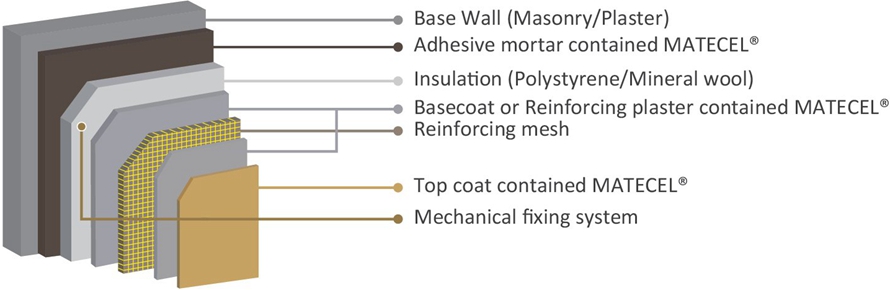

EIFS1/ETICS2

EIFS with MATECEL® promises even higher performances and excellent working efficiencies on job sites. MATECEL® leads to high sag resistance and embedding time, which are the required key properties of EIFS.

1)EIFS(Exterior Insulation and Finishing System)

2)ETICS(External Thermal Insulation composite Systems)

Better sag resistance

It is well known that mortar sag is a common problem in the filed. Better sag resistance means that mortar can be applied more efficiently to walls without sagging.

Longer time and embedding time

Open time and embedding time refers to the possible working minutes to bond insulation board or mesh on to fresh mortar is applied on the substrate. This relates to the skin formation and water evaporation of EIFS mortar. MATECEL® extends the open time and embedding time of mortars with its high water retention power and controlled skin formation properties of mortar surfaces.

Easier workability

Improve worker's woking effiency, easy spreading,no sticking to the trowel.

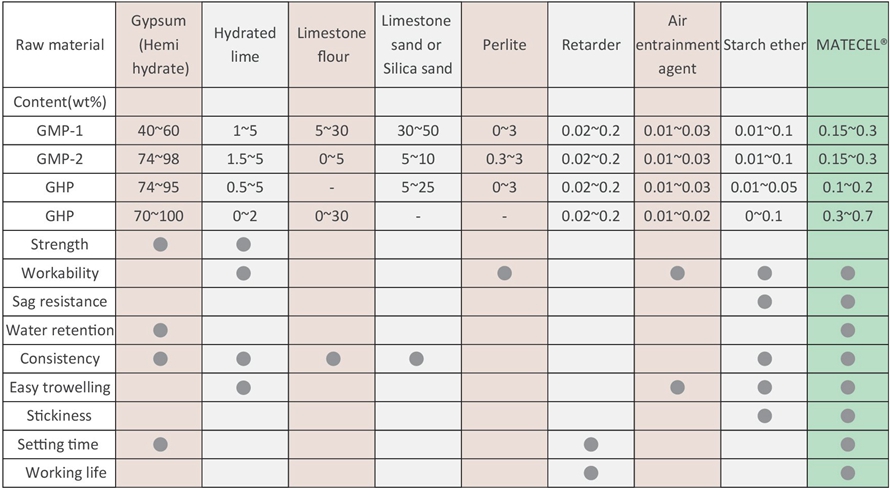

Gypsum-based Plasters

Gypsum based plaster displays different properties based on the type of formulations and resource origins.

That's why special grades of MATECEL® have been developed to meet the specific requirements of our customers. With our well-equipped, specialized gypsum application laboratories and our experienced team of application experts, we can always assist you in finding the right solutions in order to meet your requirements.

Effects of raw materials

Water retention

Water retention is the most significant property of MATECEL®, which controls workable time.Generally, water retention depends on the viscosity, fineness and dosage of MATECEL®.

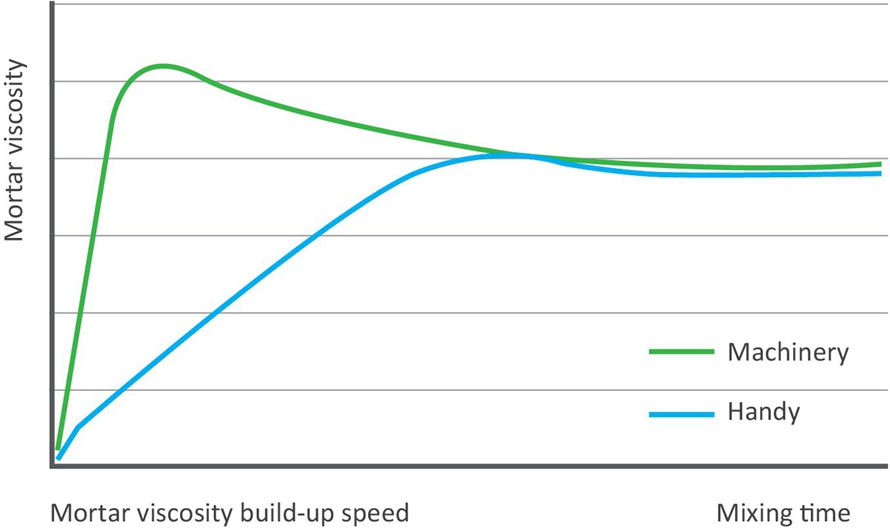

Controlling thickening speed

Special type of MATECEL® control the mortar viscosity build-up speed.

In general, the fast thickening effect of MATECEL® are necessary to obtain better sag resistance and proper rheological functions in machine plasters. On the other hand, slow thickening enables easy mixing and stable mortar viscosity as well as less lump formation in manual & finishing plasters.

Workability & Sag resistance

MATECEL® is a vital key to adjust suitable consistency in fresh mortars. Suitable consistency enables fresh plaster to attach well on walls as well as to make surfaces smooth and be applied easily without the feeling of stickiness. It can be improve better workability and a better finished product for your customers.

Skim coat

Skim coat with MATECEL® offer smooth wall surface. It ensures easy workability, long pot life, excellent water retention and more.

Effect of raw materials

Detergents

After surface treatment, MATECEL® cellulose ether has good dispersibility in cold water, which can avoid product agglomeration and uneven dissolution. After refining in the production process, it can minimize solvent residues and burning residues.

MATECEL® products are moderate without irritation. Wide pH stability can ensure its stability in the range of pH3-11.

MATECEL® cellulose ether has good consistency and water retention properties, in a way to largely improve system fluidity.

MATECEL® can better increase and stabilize the foam, improving the experience and feel when apply on skin, bring about better visual effect of the product.

MATECEL® has good anti-mold ability,color acceptance,and good compatibility with various deter-gents and cosmetic additives.

Application fields

1.Shampoo and body wash

2. Foam bath concentrate

3. Detergent /washing-up liquid

4. Cosmetics lotion

5. Alcohol hand sanitizer

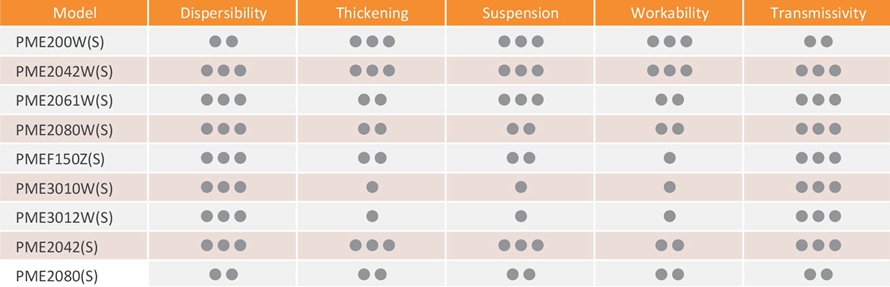

Recommended Model

MATECEL® delayed solubility grades have important characteristics which make them appropriate as thickeners in cleaner formulations:

●Easy incorporation in the formulation

●Solutions of good clarity

●Good compatibility with nonionic surfactants

●Give the product good suspension

●Good storage stability

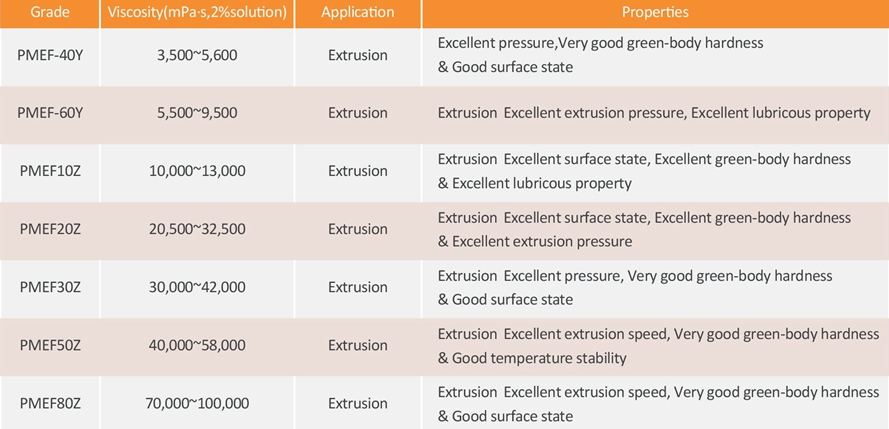

Extrusion

We are glad to say that our MATECEL® can enables differentiated & optimized products for cement extrusion and ceramic extrusion. We have set ourselves apart from our competitors and we can guarantee that you will be satisfied with every aspect of our service to delivery.

Lubrication

MATECEL® improves workability and extrud-ability of cement extrusion based products and ceramic extrusion through its lubricant properties.

Water retention

MATECEL® extends pot-life of extrusion composites because it prevents the dry out and the leakage of water from the composites and extrusion die.

Shape stability

MATECEL® leads to excellent crack resistance and shape stability during extrusion process through its binding.

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Chemical Industrial Park, Xinji City, Hebei Province, China Post Code: 052360

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. All Rights Reserved