HPMC for tile adhesive

Hydroxypropyl Methyl Cellulose (HPMC), recognized as a versatile marvel in the construction realm, transforms the dynamics of tile adhesive, also known as ceramic tile bond thickening agent and chemical additive. This innovative additive revolutionizes the way tiles adhere, presenting a game-changing solution for seamlessly bonding ceramic tiles, face bricks, and floor tiles. Its applications span from interior to exterior surfaces, gracing walls, floors, bathrooms, kitchens, and various building adornments.

(1)Bonding: The primary purpose of tile adhesive is to create a strong and durable bond between the tiles and the underlying surface. This ensures that the tiles remain firmly in place, even when subjected to various stresses such as foot traffic, moisture, and temperature changes.

(2)Support and Levelling: Tile adhesive helps create a level and even surface for tile installation. It can be used to fill in gaps, irregularities, or uneven areas on the substrate, providing a stable base for the tiles.

(3)Water Resistance: Many tile adhesives are formulated to be water-resistant or waterproof. This is especially important in areas like bathrooms, kitchens, and other wet environments where tiles are commonly used.

(4)Flexibility and Movement: Tile adhesive can offer flexibility that allows for minor movements or expansion and contraction of the substrate or the tiles themselves. This is particularly beneficial in areas prone to structural shifts.

(5)Adaptable to Different Tile Types: Tile adhesives come in various formulations to suit different tile types, sizes, and materials. There are specific adhesives for ceramic, porcelain, glass, natural stone, and other specialty tiles.

(6)Indoor and Outdoor Use: Depending on the formulation, tile adhesive can be suitable for both indoor and outdoor applications, allowing for versatile use in different settings.

(1)Advanced workability

(2)High water demand and high output

(3)Excellent sag resistance

(4)Prolonged open time

(5)Easy to spread out and not sticking to knife

Matecel can provide various cellulose ether products, and also provide special HPMC products with different viscosity grades for your tile adhesive HPMC, tailor-made for you!

• Adjusting Tile Adhesive Drying Time: By incorporating HPMC, a thin protective film forms on the tile adhesive's surface, which reduces water evaporation. This, in turn, extends the adhesive's open time.

• Enhancing Tensile Strength: The superior water retention qualities of HPMC ensure that cement retains an adequate amount of moisture during the hydration process, thereby improving its tensile strength.

• Facilitating Workability: The careful selection of the appropriate HPMC variant can make the mortar easy to apply on the wall, ultimately boosting efficiency.

• Heightening Slip Resistance: HPMC can enhance the wet mortar's bonding strength, leading to increased slip resistance.

If you are looking for high quality HPMC for sale, please feel free to contact us!

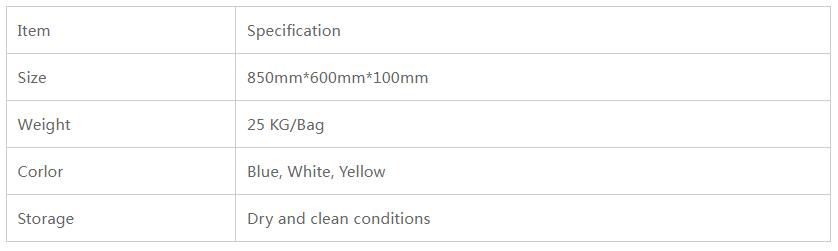

As a professional HPMC tile adhesive supplier, MATECEL provides different grades of high-quality HPMC powder:

Daily chemical grade HPMC

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Chemical Industrial Park, Xinji City, Hebei Province, China Post Code: 052360

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. All Rights Reserved